Silicone sealant or adhesive is a powerful, flexible product that can be used in many different applications. Although silicone sealant is not as strong as some sealants or adhesives, silicone sealant remains very flexible, even once it has fully dried or cured. Silicone sealant can also withstand very high temperatures, making it ideal for applications that suffer high heat exposure, such as on engine gaskets.

Cured silicone sealant exhibits excellent weather resistance, aging resistance, UV resistance, ozone resistance, high and low temperature resistance, vibration resistance, moisture resistance, and waterproofing properties; therefore, its applications are very extensive. In the 1990s, it was usually used for bonding and sealing in the glass industry, so it is commonly known as "glass adhesive."

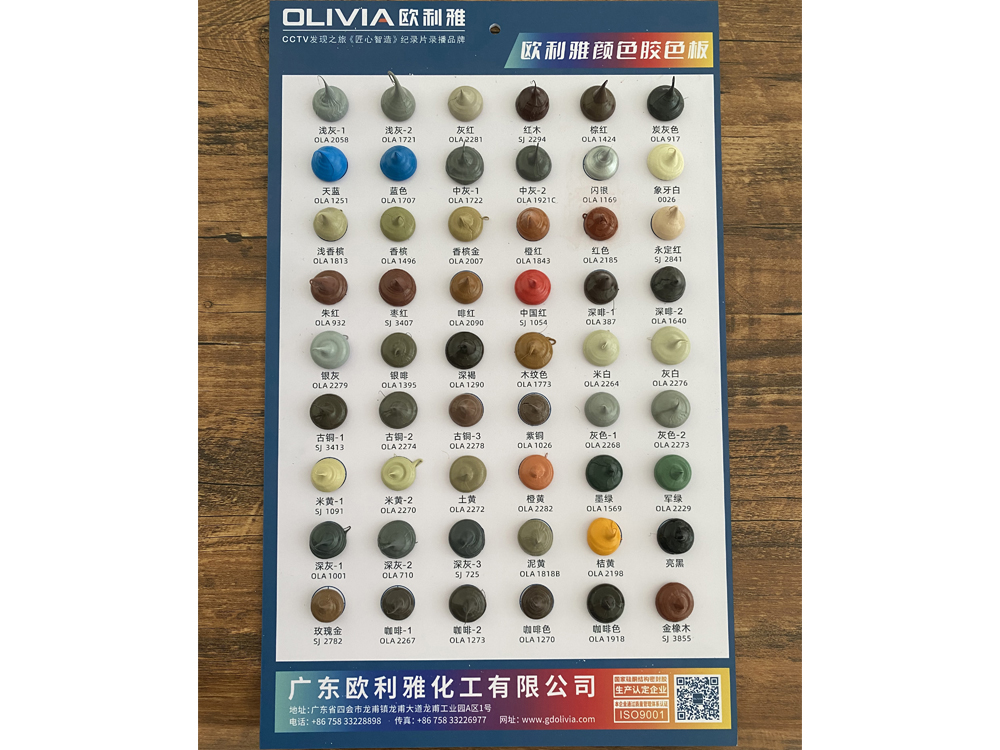

Top picture: Cured silicone sealant

Left picture: Drum packing of silicone sealant

Silicone sealant is typically based on 107(hydroxy-terminated polydimethylsiloxane), and it is composed of materials such as high-molecular-weight polymers, plasticizers, fillers, cross-linking agents, coupling agents, catalysts, etc. Commonly used plasticizers include silicone oil, white oil, etc. Commonly used fillers include nano-activated calcium carbonate, heavy calcium carbonate, ultrafine calcium carbonate, fumed silica, and other materials.

Silicone sealants come in a variety of different forms.

According to the type of storage, it is divided into: two (multi) component and single component.

Two (multi) component means that silicone sealant divided into two groups (or more than two) parts A and B, any one component alone can not form curing, but after the two components (or more than two) parts are mixed, they will produce cross-linking curing reaction to form elastomers.

The mixture must be made immediately before using it, which makes this type of silicone sealant rather tricky to use.

Silicone sealant may also come as a single product, with no mixing required. One type of single-product silicone sealant is called Room Temperature Vulcanizing (RTV). This form of sealant starts to cure as soon as it is exposed to the air – or, more precisely, the moisture in the air. Therefore, it is necessary that you work quickly when using RTV silicone sealant.

Single-component silicone sealant can be roughly divided into: deacidification type, dealcoholization type, deketoxime type, deacetone type, deamidation type, dehydroxylamine type, etc. according to the different crosslinking agents (or small molecules generated during curing) used. Among them, deacidification type, dealcoholization type and deketoxime type are mainly used in the market.

Deacidification type is methyl triacetoxysilane (or ethyl triacetoxysilane, propyl triacetoxysilane, etc.) as a crosslinking agent, which produces acetic acid during curing, commonly known as "acid glue". Its advantages are: good strength and transparency, fast curing speed. Disadvantages are: irritating acetic acid smell, corrosion of metals.

Dealcoholization type is to methyl trimethoxysilane (or vinyl trimethoxysilane, etc.) as a crosslinking agent, its curing process produces methanol, commonly known as "alcohol-type glue". Its advantages are: environmental protection, non-corrosive. Disadvantages: slow curing speed, storage shelf life is slightly poor.

Deketo oxime type is methyl tributyl ketone oxime silane (or vinyl tributyl ketone oxime silane, etc.) as a crosslinking agent, which produces butanone oxime during curing, commonly known as "oxime type glue". Its advantages are: no too big smell, good adhesion to various materials. Disadvantages: corrosion of copper.

According to the use of products divided into: structural sealant, weather resistant sealant, door and window sealant, sealant joint, fire-proof sealant, anti-mildew sealant, high temperature sealant.

According to the color of the product to points: conventional color black, porcelain white, transparent, silver gray 4 kinds, other colors we can carry out according to customer requirements toning.

There are a variety of other, more technologically advanced forms of silicone sealant as well. One type, called pressure sensitive silicone sealant, has a permanent tackiness and adheres with deliberate pressure – in other words, although it will always be “sticky,” it won’t stick if something simply brushes or rests up against it. Another type is called UV or radiation cured silicone sealant, and uses ultraviolet light to cure the sealant. Finally, thermoset silicone sealant requires exposure to heat in order to cure.

Silicone sealant may be used in a variety of applications. This type of sealant is frequently used in automotive and related applications, such as an aid for sealing an engine, with or without gaskets. Because of its superior flexibility, the sealant is also a good choice for many hobbies or crafts.

Post time: Dec-29-2023